The side decks are merely screwed on so we have a good interface and everything is lined up vertically for smooth transitions and no gaps on the bolsters when they're built. Went with the biax tape again on this, no woven, I'll just be doing a little fairing compound and calling it good. Uniflite decided to do a finish layer of roving, then just gelcoat and spatter paint, so I'd be stuck doing the ENTIRE interior for fairing. Meh, nah, I'll go with the factory program of a textured paint or a spatter paint.

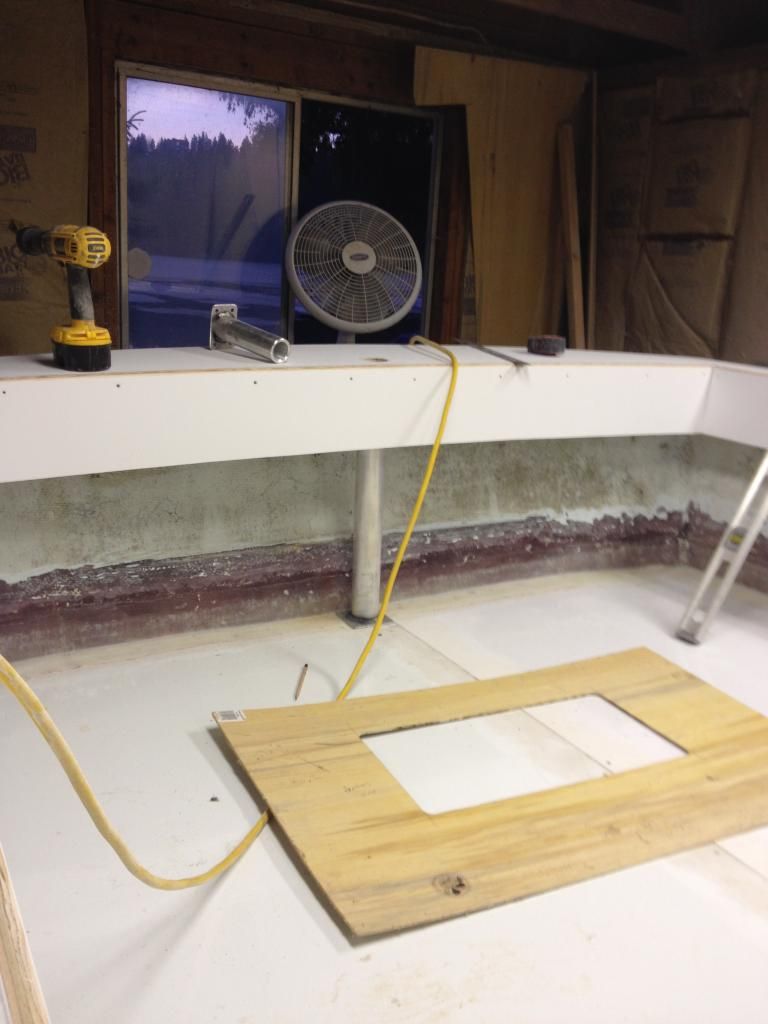

Engine splash protection is in place as well. This is glued to big cleats, then backed up with stainless screws through the sole. Opted for the belt-and-suspenders approach here because there's a bit of a span, and I wanted the sole to feel bulletproof under foot.

Lastly, since this is going to be our summertime surf/party/play boat over here in Spokane, it had to have the ability to tow humans. Looked long and hard at different options, including a custom T-top set up for towing like the MasterCraft CSX series. After thinking long and hard about it, I ended up picking up a removable tow post from Great Lakes. Rather than having the rope constantly annoying the occupants, it will hang out off the stern. Should still be tall enough for the mediocre wakeboarders we hang with, and will be *perfect* for surfing (the reason my wife actually got excited about this project).

Off to work again, then with 3 whole days off, let's shoot for getting the side decks glued on, maybe some hanging knees if she needs them, fiberglass in the engine rim, hinge the engine cover, and start whacking together a console! If'n we get the console ironed out right, drop in the steering/harness/throttle, and it is sea trial time...

E